8 Manufacturing Plant Quality Control Tips

Quality control plays an essential role in the manufacturing process, ensuring the safety and reliability of products. As a business owner, you must implement quality control measures throughout the production process to maintain a high standard.

But this is easier said than done. Implementing quality control measures can be challenging, from training teams to managing resources. But we intend to help.

This article will cover various tips to help you implement quality control in your manufacturing plant. We'll cover topics such as developing an efficient quality control system, utilizing automated inspection processes, and training your staff in quality control techniques.

Each tip will provide insights into ensuring the highest quality standards for your products. We'll also discuss the potential issues that may arise when implementing these measures and the steps you can take to prevent them.

Read on.

Develop an Effective Quality Control System

A structured quality control system should be tailored to your needs and industry standards. Defining quality control policies and procedures that align with the production process is essential.

Establish key performance indicators (KPIs) to measure progress, such as product inspection rates, and determine the testing frequency. This will ensure that your team consistently monitors and assesses product quality.

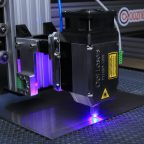

Utilize Automated Inspection Processes

Automated systems reduce human error from manual inspections and help streamline processes. Additionally, automated inspection systems allow for faster results than traditional methods, thus improving overall turnaround time for production runs.

Train Staff in Quality Control Techniques

Ensure that your staff is well-trained in quality control techniques. Provide ongoing training and educational programs to ensure everyone is familiar with the methods used in your manufacturing plant.

Additionally, encourage open communication between staff members so they can raise any potential issues during quality control checks.

Employ Quality Control Audits

Quality control audits are a great way to validate your procedures' effectiveness further. These inspections should involve reviewing documents such as specifications and drawings and observing processes on the production floor.

This will help identify any areas for improvement within the facility, allowing you to make necessary changes quickly and efficiently.

Utilize Statistical Process Control (SPC)

Statistical process control (SPC) is a useful tool for monitoring and controlling production processes. It helps to identify any potential problems before they become major issues, allowing you to take corrective action in time.

SPC collects data over time to detect abnormalities quickly and accurately, making it an essential quality control measure.

Establish Quality Objectives

Establish specific objectives to ensure your manufacturing plant meets the required quality standards. These should be measurable and achievable goals that align with industry standards.

Additionally, review these objectives regularly to ensure they are still relevant and achievable.

Utilize Quality Assurance Tools

From Metrology Software Products to inspection equipment, various tools are available to ensure your products' quality. Quality assurance teams should be able to identify and utilize the best methods for inspecting products to guarantee consistency and accuracy in results.

Implement a Quality Improvement Plan

Quality improvement plans are an effective way to ensure that quality control measures remain up-to-date with industry standards. Establishing a plan requires identifying areas where improvements can be made, setting goals, and tracking progress over time.

This will keep your manufacturing plant running smoothly while ensuring high levels of product quality.

Final Word

Quality control is essential for any manufacturing plant. Implementing these tips ensures that your facility meets the required quality standards while improving efficiency and productivity.

Remember to keep track of progress and review settings regularly to avoid issues and ensure that your customers receive top-notch products. If you have any questions or concerns, feel free to ask us in the comments!