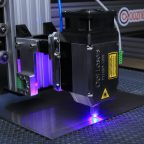

Water jet cutting machines - uses and benefits

There are all sorts of machines used in manufacturing, but one of the most versatile is the water jet cutter. This machine uses a high-pressure stream of water to cut through almost any material. It can be used for precision cutting or for the rapid removal of large amounts of material. Here's a look at some of the key uses of water jet cutting machines and how they can benefit your business. Let's kick off with some common uses of waterjet cutting machines

Cutting And Shaping Of Metal

A water jet cutting machine by Techni Waterjet is a tool that is used for cutting and shaping metal. The machine uses a high-pressure stream of water to cut through the metal. This type of machine is very versatile and can be used for a variety of different projects. For example, the machine can be used to cut metal pipes or to shwater jet cutting machine by Techni Waterjetape metal sheets into different shapes. In addition, the machine can be used to engrave designs into metal. Water jet cutting machines are very precise and can produce clean, sharp cuts. This type of machine is often used in manufacturing and engineering applications.

Manufacturing Of Medical Devices

Water jet cutting machines have a wide range of applications in the medical device industry. They can be used to cut a variety of materials, including metals, plastics, and composites. Water jet cutting machines can also be used to create intricate designs and patterns on medical devices. In addition, water jet cutting machines can be used to machine complex shapes and geometries. As a result, water jet cutting machines are an essential tool for the manufacturing of medical devices.

Production Of Car Parts

A water jet cutting machine is a powerful tool that can be used in the production of car parts. By using high-pressure water, it can cut through metal, glass, and other materials with ease. The machine is often used to create intricate designs or to cut out large pieces that will be used in the construction of a car. In addition to its usefulness in production, a water jet cutting machine can also be used for maintenance and repair work on cars. By having this machine on hand, you can quickly and easily make the necessary repairs to keep your car running smoothly.

The use of water jet cutting machines has its own package of benefits such as;

Increased Accuracy

In any manufacturing process, accuracy is key. Water jet cutting machines offer a high degree of accuracy, thanks to their ability to cut with precision using extremely high-pressure streams of water. This technology can be used to cut a wide variety of materials, including metal, stone, glass, and composites. Water jet cutting machines have become increasingly popular in recent years due to their versatility and precision. In addition, waterjet cutting machines are much quieter than traditional methods such as sawing or grinding. This makes them ideal for use in noise-sensitive environments such as hospitals or schools. As water jet cutting technology continues to advance, we can expect even greater levels of accuracy and precision from these machines.

Increased Efficiency

A water jet cutting machine is a versatile and powerful tool that can be used for a variety of applications. One of the biggest advantages of using a water jet cutter is the increased efficiency it provides. Water jet cutters can cut through materials quickly and easily, without the need for pre-drilling or other preparations. This can save a lot of time, especially when working with larger pieces of material. In addition, water jet cutters can be used to cut intricate shapes and patterns that would be difficult or impossible to create with other methods. As a result, water jet cutting machines offer a high level of versatility and efficiency, making them an essential tool for any shop or factory.

Less Waste

When you’re working with materials like metal, wood, or stone, it’s important to be as efficient as possible to avoid wasting material. That’s where a water jet cutting machine comes in. Water jet cutting machines use high-pressure streams of water to cut through materials. This method is highly precise, so there is very little wasted material. In fact, water jet cutting machines can have an accuracy of up to 0.005 inches. This precision means that waterjet cutting is often used for delicate or intricate projects, such as creating detailed designs in metalwork or carving out stone sculptures. Not only is water jet cutting more efficient than other methods, but it also produces less noise and dust, making it a cleaner and safer option overall.

Higher Quality Products

A water jet cutting machine is a powerful and precise tool that can be used to cut a variety of materials. Unlike traditional methods such as saws and lasers, water jet cutting produces a clean, smooth edge with no heat-affected zone. This means that water jet-cut parts are less likely to warp or crack, and they can be finished more easily. In addition, water jet cutting produces very little noise and dust, making it ideal for use in sensitive environments. As a result, water jet cutting is becoming increasingly popular for a wide range of applications, from aerospace manufacturing to food processing.

In Conclusion:

Water jet cutting machines are versatile tools that can be used for a variety of purposes. In this blog post, we’ve shared just a few examples of how water jet cutters are used in manufacturing and production as well as some benefits to expect when using a water jet cutting machine. A water jet cutting machine is for sure must have for manufacturing or production.